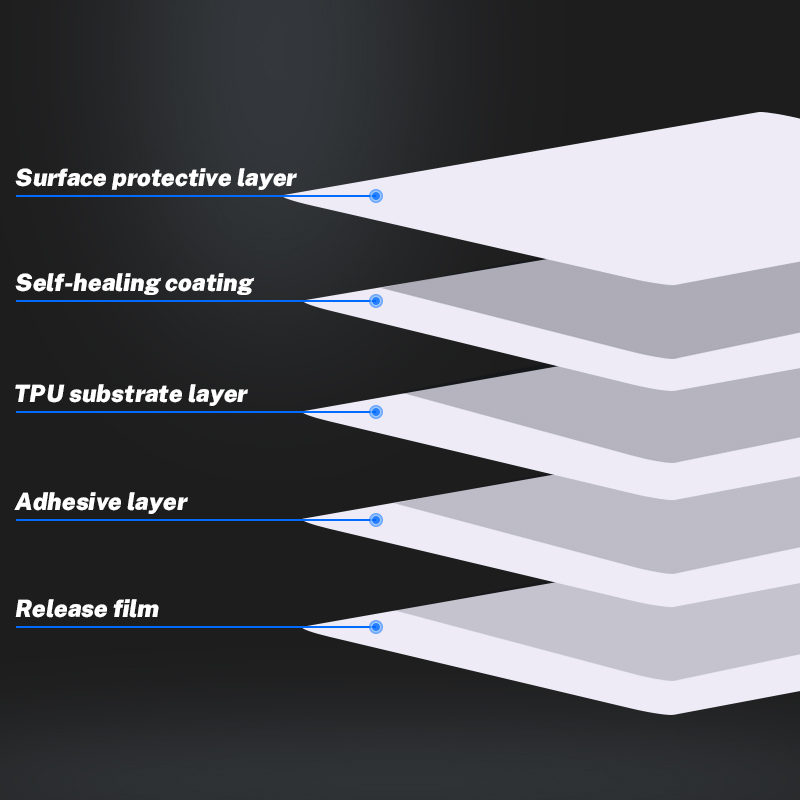

TPU Color Changing Film is a TPU base material film with abundant and various colors to change the whole car or partial appearance by covering and pasting. BOKE's TPU Color Changing Film can effectively prevent cuts, resist yellowing, and repair scratches. TPU Color Changing Film is currently the best material on the market and has the same function as a Paint Protection Film of brightening the color; there is a uniform thickness standard, the ability to prevent cuts and scrapes is greatly improved, the texture of the film is far more than PVC Color Changing Film, almost to achieve 0 orange peel pattern, BOKE's TPU Color Changing Film can protect the car paint and color change at the same time.

As one of the popular methods to change the color of a car, the development of color change film has been a long time, and PVC Color Changing Film still dominates the mainstream market. With the extension of time, wind-blown and sun-dried, the film itself will gradually weaken its quality, with chafing, scratches, orange peel lines, and other problems. The emergence of TPU Color Changing Film can effectively solve the PVC Color Changing Film issues. This is the reason why car owners choose TPU Color Changing Film.

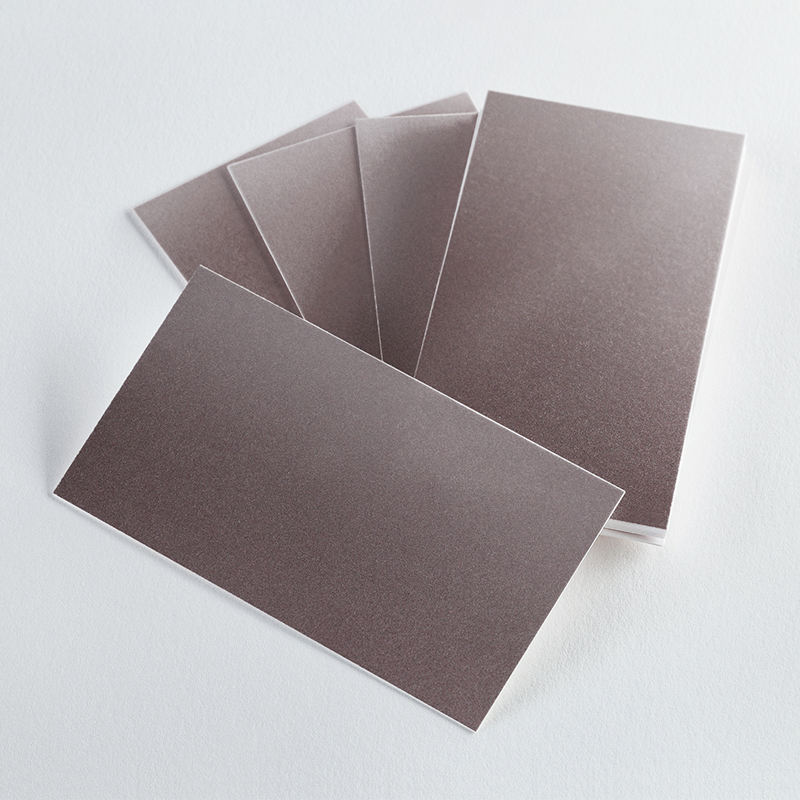

TPU Color Changing Film can change the vehicle's color and painting or decal as you like without hurting the original paint. Compared with complete car painting, TPU Color Changing Film is easy to apply and protects the vehicle's integrity better; the color matching is more independent, and there is no trouble with color differences between the different parts of the same color. BOKE's TPU Color Changing Film can be applied to the whole car. Flexible, durable, crystal clear, corrosion resistant, wear-resistant, scratch resistant, paint protection, has no residual adhesive, easy maintenance, environmental protection, and has multiple color options.

PVC: It's actually resin

PVC is the abbreviation for polyvinyl chloride. It is a polymer formed by the polymerization of vinyl chloride monomer (VCM) with initiators such as peroxides and azo compounds, or under the action of light and heat, according to the mechanism of free radical polymerization. Vinyl chloride homopolymer and vinyl chloride copolymer are collectively referred to as vinyl chloride resin.

Pure PVC has very average heat resistance, stability, and tension; But after adding the corresponding formula, PVC will exhibit different product performance. In the application of color changing films, PVC has the most diverse colors, full colors, and low prices. Its disadvantages include easy fading, peeling, cracking, etc.

PFT: wear-resistant, high-temperature resistant, and good stability

PET (Polyethylene terephthalate) or commonly known as polyester resin, although both are resins, PET has some very rare advantages:

It has good mechanical properties, with an impact strength 3-5 times that of other films, and good bending resistance. Resistant to oil, fat, dilute acids, alkalis, and most solvents. It can be used for a long time in the temperature range of 55-60 ℃, can withstand high temperatures of 65 ℃ for short periods of time, and can withstand low temperatures of -70 ℃, and has little impact on its mechanical properties at high and low temperatures.

Gas and water vapor have low permeability and excellent resistance to gas, water, oil, and odor. High transparency, can block ultraviolet rays, and has good glossiness. Non toxic, odorless, with good hygiene and safety, it can be directly used for food packaging.

In terms of color modification film application, PET color modification film has good smoothness, good display effect when stuck on the car, and there is no traditional orange peel pattern when stuck. PET color modification film has honeycomb air duct, which is convenient for construction and not easy to offset. At the same time, its anti creep, fatigue resistance, friction resistance, and dimensional stability are all very good.

TPU: High performance, more value preservation

TPU (Thermoplastic polyurethanes), also known as thermoplastic polyurethane elastomer rubber, is a polymer material formed by the joint reaction and polymerization of various low molecules. TPU has excellent characteristics of high tension, high tensile strength, toughness, and aging resistance, making it a mature and environmentally friendly material. The advantages are: good toughness, wear resistance, cold resistance, oil resistance, water resistance, aging resistance, climate resistance, etc. At the same time, it has many excellent functions such as high waterproof, moisture permeability, wind resistance, cold resistance, antibacterial, mold resistance, warmth preservation, UV resistance, and energy release.

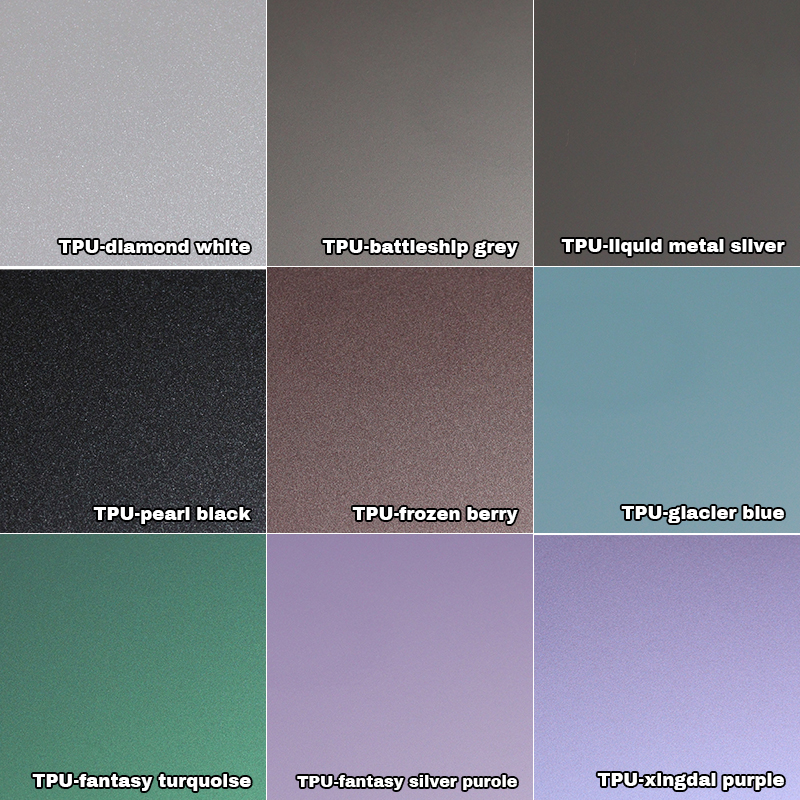

In the early days, TPU was made of invisible car clothing material, which was the best material for car film. TPU has now been applied in the field of color modification films. Due to its difficulty in coloring, it is more expensive and has fewer colors. Generally, it only has relatively monotonous colors, such as red, black, gray, blue, etc. The color changing film of TPU also inherits all the functions of invisible car jackets, such as scratch repair and protection of the original car paint.

The performance, price, and material comparison of color modification films made of PVC, PET, and TPU materials are as follows: Quality comparison: TPU>PET>PVC

Color quantity: PVC>PET>TPU

Price range: TPU>PET>PVC

Product performance: TPU>PET>PVC

From the perspective of service life, under the same conditions and environment, the service life of PVC is approximately 3 years, PET is approximately 5 years, and TPU can generally be around 10 years.

If you pursue safety and hope to protect the car paint in the event of an accident, you can choose TPU color changing film, or apply a layer of PVC color changing film, and then apply a layer of PPF.

Post time: May-04-2023