Thermoplastic polyurethane (TPU) not only has the rubber properties of cross-linked polyurethane, such as high strength, high wear resistance, but also has the thermoplastic properties of linear polymer materials, so that its application can be extended to the plastic field. Especially in recent decades, TPU has become one of the fastest developing polymer materials.

TPU has excellent high tension, high tension, toughness, and aging resistance characteristics, making it a mature and environmentally friendly material. It has high strength, good toughness, wear resistance, cold resistance, oil resistance, water resistance, aging resistance, and weather resistance, which are incomparable to other plastic materials. At the same time, it has high waterproof and moisture permeability, wind resistance, cold resistance, antibacterial properties, mold resistance, and many excellent functions, such as warmth preservation, UV resistance, and energy release.

TPU has a wide range of operating temperatures. Most products can be used for a long time in the range of -40-80 ℃, and the short-term operating temperature can reach 120 ℃. The soft segments in the segment structure of TPU macromolecules determine their low-temperature performance. Polyester type TPU has lower low-temperature performance and flexibility than polyether type TPU. The low-temperature performance of TPU is determined by the initial glass transition temperature of the soft segment and the softening temperature of the soft segment. The glass transition range depends on the content of the hard segment and the degree of phase separation between the soft and hard segments. As the content of hard segments increases and the degree of phase separation decreases, the glass transition range of soft segments also widens accordingly, which will lead to poor low-temperature performance. If polyether with poor compatibility with the hard segment is used as the soft segment, the low-temperature flexibility of TPU can be improved. When the relative molecular weight of the soft segment increases or TPU is annealed, the degree of incompatibility between the soft and hard segments will also increase. At high temperatures, its performance is mainly maintained by hard chain segments, and the higher the hardness of the product, the higher its service temperature. In addition, the high-temperature performance is not only related to the amount of chain extender, but also influenced by the type of chain extender. For example, the use temperature of TPU obtained by using (hydroxyethoxy) benzene as a chain extender is higher than that of TPU obtained by using butanediol or hexanediol as a chain extender. The type of diisocyanate also affects the high-temperature performance of TPU, and different diisocyanates and chain extenders as hard segments exhibit different melting points.

At present, the application scope of TPU film is becoming wider and wider, and it is gradually expanding from traditional shoes, textiles, clothing to aerospace, military, electronics and other fields. At the same time, TPU film is a new industrial material that can be continuously modified. It can expand its application field through raw material modification, material formula adjustment, production process optimization and other ways, thus giving TPU film more space to use. In the future, industrial technology level will be improved, The application of TPU will go further.

What are the current applications of TPU materials in our company?

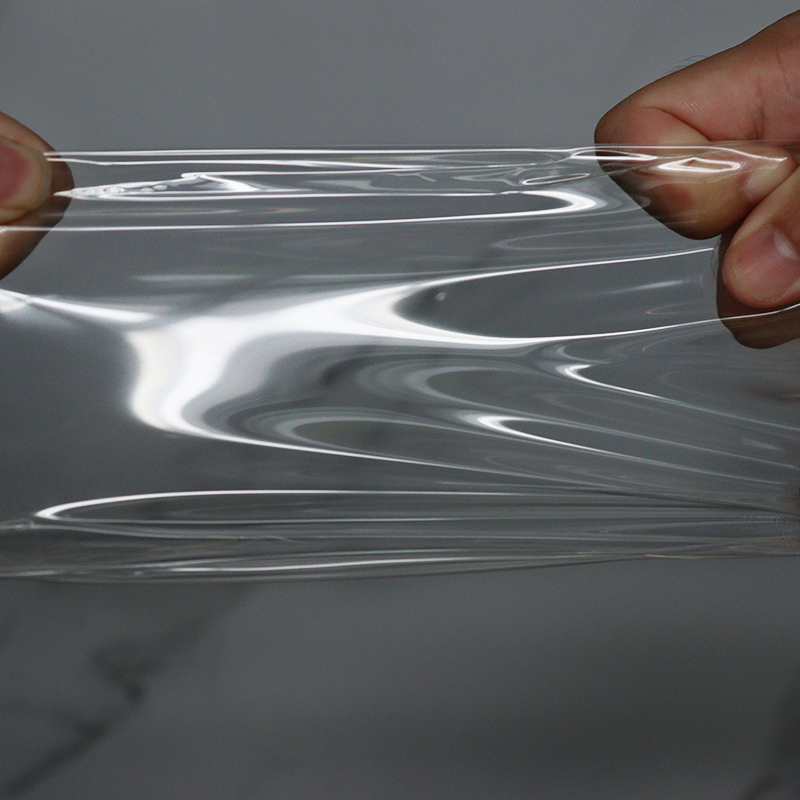

As cars play an increasingly important role in our lives, the demand for vehicle protection among car owners is also increasing. The TPU material paint protection film is the perfect solution to address this demand.

One of the characteristics of TPU paint protection film is its excellent tear resistance, which can effectively resist the impact of sharp objects such as gravel and sand on the road, and protect the body from scratches and dents. There is no longer a need to worry about possible damage during driving, and you can focus more on the road and driving experience when driving.

In addition, TPU paint protection film has excellent weather resistance. Whether it's strong sunlight, acid rain corrosion, or pollutants, this paint protection film can reliably protect the car's paint from damage, keeping the car always with a bright appearance.

What's even more surprising is that our TPU material paint protection film also has self-healing function. After being slightly scratched, its material can repair itself in a suitable warm environment, allowing the body to recover as before and extending the service life of the paint protection film.

This TPU material paint protection film not only provides comprehensive protection, but also places great emphasis on environmental protection. The paint protection film made of environmentally friendly materials will not cause any burden on the environment, which is in line with the pursuit of green travel by modern people.

The launch of TPU material paint protection film marks a revolution in the field of automotive protection, providing more advanced and reliable protection solutions for car owners. Embrace green protection, let our cars and the earth breathe together.

Please scan the QR code above to contact us directly.

Post time: Aug-03-2023