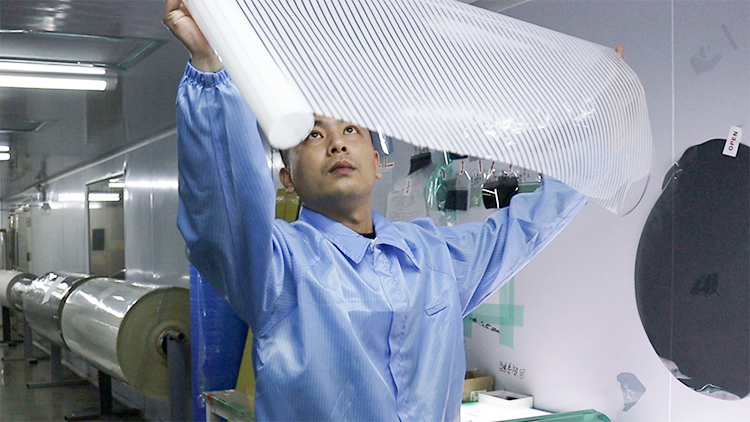

Our factory in Chaozhou, Guangdong Province

| From TPU masterbatch to original TPU film |

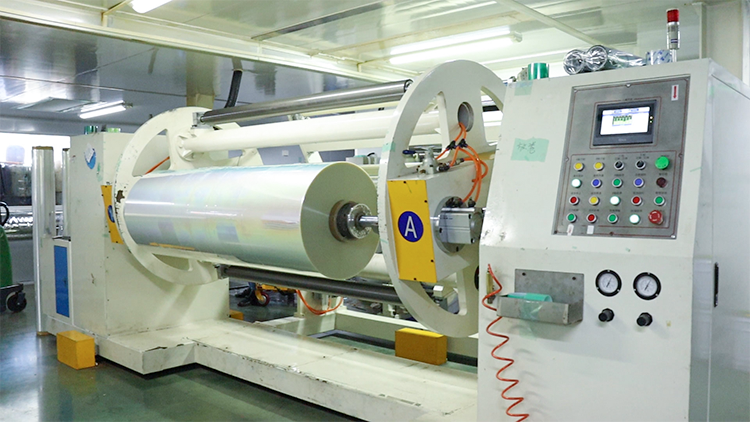

TPU is a non-stretch, non-directional, flat extruded film produced from TPU pellets by melt saliva quenching, the original TPU film. It has excellent properties such as high elasticity and abrasion and corrosion resistance. Generally speaking, if you choose the suitable TPU pellets, you will have made a good film. The melt saliva production method is characterized by fast production speed and high output compared to the common blown film on the market. The film's transparency, gloss, and thickness uniformity are excellent.

| Adhesive backing process |

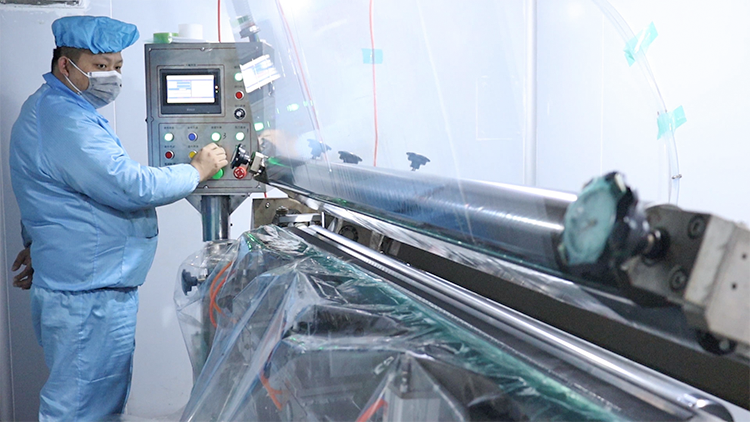

The adhesive backing process for paint protection films is simply the application of adhesive backing, which is the same as the principle of spraying paint, requiring a base coat followed by a color coat. The same applies to the backing, which is applied by a coating process in which the film is first scanned with an electron beam, then the glue is applied to the laminate and then laminated to the film surface of the TPU substrate.

Of course, all this is done by machine only, and each roll of BOKE's paint protection film is produced using the world's most advanced precision coating production equipment, using particle synthesis technology and precision coating technology.

The backing process is very technically demanding and requires matching different materials. If you do not grasp the glue formula well, you will often experience glue loss.

| The coating process |

The coating process is understood as a nano-crystallization of the film surface, which adds a layer of nano-repair coating material to the TPU substrate, equivalent to an additional layer of protection. The coating process is also the core competence of each paint mask brand. Once the coating process is not up to standard, there will be many performance problems, such as yellowing and poor stain resistance.

| Finished Film |

Once the above process has been completed, the lacquer protection film is a finished product.

But do you think that's all?

No, after the film has been produced, it is necessary to cut a part of the film for sample testing to check whether the quality of the film meets the production standards, and finally, the whole roll is cut and packed for transport.

2000-2009

Established Beijing Qiaofeng Weiye Sales Department. Successive branches were set up in Beijing, Chengdu, Zhengzhou, and Chongqing.

2010

Established Shuyang Langkepu New Material Technology Co., Ltd. and built a factory in Mao Wei Industrial Zone, Muyang County, Suqian City, Jiangsu Province, and set up a distribution point in Linyi City, Shandong Province.

2011-2014

Established Yiwu branch, Kunming, Guiyang, Nanning, and other distribution offices.

2015

Established Hangzhou Qiaofeng Automotive Products Co., Ltd. warehousing and distribution center, the largest factory direct sales warehousing and distribution operation center of the branch in the country.

2017

Established a new factory and bought land to build a factory located in A01-9-2, Zhangxi Low Carbon Industrial Zone, RaoPing County, Chaozhou City, covering an area of 1.6708 hectares. We also introduced the world's most advanced EDI coating line equipment from the United States.

2019

To become one of the largest film manufacturers in the world, the Group relocated to Guangzhou, an international free trade port city in China, and established "Guangdong Boke New Film Technology Co., Ltd." to sail the global trade market and the foreign trade import and export window was officially opened.

2023

Continue to provide the best service and film solutions to our global corporate partners.

Post time: Mar-30-2023