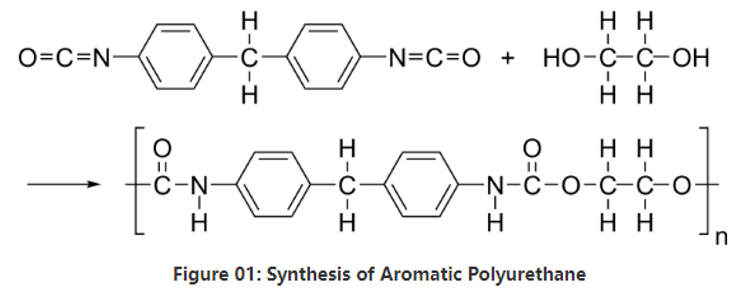

1: Aromatic polyurethane Masterbatch

Aromatic polyurethanes are polymers that contain a cyclic aromatic structure. Containing an aromatic ring, it is brittle. It is unstable in sunlight and has a tendency to turn yellow within 1-2 years. It is not heat resistant, unstable to UV rays, and not durable in sunlight.

2: Aliphatic polyurethane Masterbatch

Aliphatic polyurethane is a flexible polymer with no aromatic structure. It is UV stable, very durable in sunlight, and retains its color well over time.

Aromatic polyurethane Masterbatch

Aliphatic polyurethane Masterbatch

Do you know the production process of TPU?

Dehumidification and drying: molecular sieve dehumidification desiccant, more than 4h, moisture <0.01%

Process temperature: refer to the raw material manufacturers recommended, according to the hardness, MFI settings

Filtration: follow the cycle of use, to prevent black spots of foreign matter

Melt pump: extrusion volume stabilization, closed-loop control with the extruder

Screw: Select low shear structure for TPU.

Die head: design the flow channel according to the rheology of aliphatic TPU material.

Processing technology points

TPU masterbatch: TPU masterbatch after high temperature

casting machine;

TPU film;

Coating machine gluing: TPU is placed on the thermosetting/light-setting coating machine and coated with a layer of acrylic glue/light-curing glue;

Laminating: Laminating the PET release film with the glued TPU;

Coating (functional layer): nano-hydrophobic coating on TPU after lamination;

Drying: drying the glue on the film with the drying process that comes with the coating machine; this process will generate a small amount of organic waste gas;

Slitting: According to the order requirements, the composite film will be slit into different sizes by the slitting machine; this process will produce edges and corners;

Winding: the color change film after slitting is wound into products;

Finished product packaging: packaging the product into the warehouse.

Tips

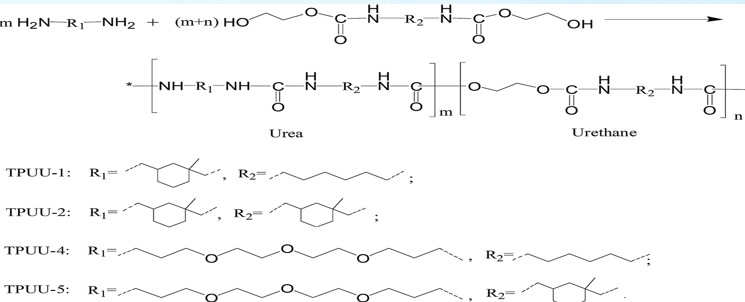

1.TPU film is a film made on the basis of TPU granule material by special processes such as calendering, casting, blown film, coating and so on.

2. Structurally speaking, TPU paint protection film is mainly composed of functional coating, TPU base film and adhesive layer composite.

TPU Functional Characteristics

Seif-Healing

Anti-Fouling

Anti-Scratch

Anti-Yellowing

Anti-Oxidation

Puncture-Resistant

Corrosion Resistance

Nano Hydrophobic

Aliphatic Masterbatch

Strong Elasticity

Claims about anti-yellowing

Normally, the warranty period is five to ten years,depending on the product.The main warranty is that the product will not be hydrolyzed, cracked, hot-melted and naturally aged against yellowing by less than 2% per year. Any good product will turn yellow, it just depends on the size of the yellowing index, and our products guarantee that the anti-yellowing of natural aging within five years is less than 10%。

Anti-yellowing TPU

Yellowing depends on the substrate, we are using the U.S. imported aliphatic masterbatch, the yellowing index will not exceed 10% five years after use.

Repair function

1. Self-repair: scratches from car wash, sun flare, car interior scratches and other fine scratches are automatically repaired by weather heating.

2. Thermal repair: through the heating principle, such as hot air gun, lighter, blow dryer and other heating repair.

3. Lotus leaf-like hydrophobic

Anti-fouling and anti-corrosion: Advanced imported nano hydrophobic coating, resisting various acid rain, insect bodies, tree resin and other pollution.

4. Improve the brightness of car paint

Tested by professional instruments, depending on the follow-up products, the gloss of the film surface is up to 45%, the lowest is 30%, enjoy the feeling of a new car.

5. Portable construction performance

International glue formula (the United States Ashland (ashland), Germany Henkel (henka) and boke independent research and development of glue, medium-sized glue, greatly saving construction time, saving construction costs.

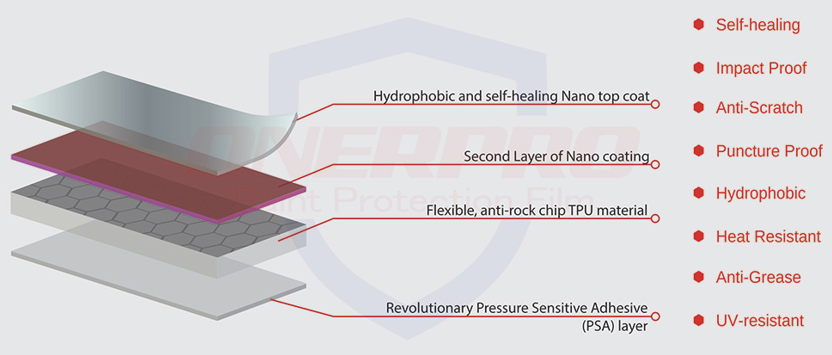

It is mainly used in the middle of glass interlayers such as architectural and indoor escalator glass.

PVB (Polyvinyl Butyral) Laminated Glass

PVB glass interlayer film is made of polyvinyl butyral resin, plasticizer 3GO (triethylene glycol diisooctanoate) plasticized extrusion and molding of a polymer material.

The thickness of PVB glass laminated film is generally 0.38mm and 0.76mm two kinds, has good adhesion to inorganic glass, with transparent, heat, cold, moisture, mechanical strength and high characteristics.

PVB film is mainly used for laminated glass, is sandwiched between two pieces of glass into a layer of polyvinyl butyral as the main component of the PVB film.PVB laminated glass is widely used in construction, automotive and other industries due to its safety, heat preservation, noise control and isolation of ultraviolet rays and many other functions.

SGP (Sentry Glas Plus) Ionic Interlayer Film

SGP is a high-performance laminated material, SGP film as an interlayer produced laminated glass, with transparency, high mechanical degree, impact resistance since the deacon's characteristics, is currently the higher safety performance of the glass varieties, with high security such as anti-scape, bullet-proof, typhoon and so on.

SGP laminated glass application of public buildings, glass barriers, balcony doors and windows, indoor partition stairwell glass and escutcheon.

SGP laminated glass can withstand greater pressure and can meet the needs of the bright observation, can be used as submarine windows, deep-water spyglass, ornamental aquariums and so on. It can be used as submarine windows, deep-water spyglass, ornamental aquariums, etc. It is also used as safety glass for ultra-high-rise buildings and large public buildings.

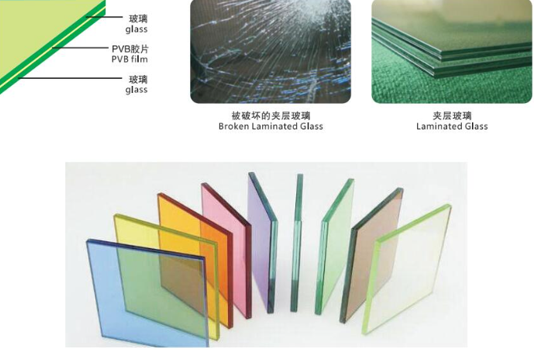

TPU Thermoplastic Polyurethane Rubber

Thermoplastic polyurethane elastomer, also known as thermoplastic polyurethane rubber, referred to as TPU, is a (AB)n-type block linear polymer, A is a high molecular weight (1000~6000) polyester or polyether, B is a glycol containing 2~12 straight-chain carbon atoms, and the chemical structure of the AB inter-chain segments is diisocyanate.

tpu is an environmentally friendly polymer with excellent performance, both the elasticity of rubber and the hardness of plastic, and has excellent thermodynamic properties, light transmittance, abrasion resistance, high ultraviolet, toughness, puncture resistance, rebound and easy to process and so on.

It is used in the fields of automobile parts, construction, food, medical, electronics, shoes, clothing and so on. With the increasing market demand in the modern glass assembly industry, the application of tpu film in glass interlayer is also increasing.

Each Advantage

Status: At present, architectural glass and automobile interlayer are mainly made of PVB, EVA and SGP materials, among which EVA film layer is weak in UV resistance and has been eliminated, SGP film is not noise-proof and water moisture cannot be diluted in case of water, thus limiting its application, so TPU material is more suitable for laminated glass than PVB.

First: Properties of PVB.

Because PVB can not have high elasticity and high tensile, this for the bending of the glass is more helpful and safety performance improvement and importance.

At the same time, PVB film laminated glass exposed edges are susceptible to moisture open glue, long time use is prone to yellowing phenomenon, so PVB film laminated glass can be used for general glass curtain wall, is not suitable for high-performance glass curtain wall.

Compared with PVB material, TPU high-performance film can be effectively combined with PC board (plexiglass) to make bulletproof glass and smash-proof glass.

Second: Properties of SGP (SuperSafeGlas).

SuperSafeGlas material has a slow absorption rate of water, but the absorption of water will also lead to a reduction in the bonding force, moisture can not be released through a relatively dry environment

Unlike PVB, SuperSafeGlas materials do not adhere to each other, so there is no intermediate barrier film, and there is no need to control the temperature of unopened SuperSafeGlas materials during storage.

SGP is not noise resistant

Compared with SGP material, TPU combined with PC board has excellent electrical insulation, elongation, dimensional stability and chemical resistance, high strength, water resistance, noise resistance, heat resistance and cold resistance.

TPU instead of PVB four major features

Anti-puncture penetration: TPU film has a very high strength and penetration resistance, is pvb film 5-10 times through, can be effectively applied to the bank's bullet-proof glass and villa anti-smash glass.

Weather resistance: TPU film cold, aging, high temperature, weather resistance, and will not react with other materials.

Toughness: TPU's own structure gives the material a very high toughness, different from the pvb film brittle characteristics of large

Ultraviolet performance: TPU block more than 99% of the ultraviolet short-wave light irradiation, high transmittance, with heat insulation and radiation effects so as to help avoid harm due to ultraviolet radiation.

TPU is better than PVB, SGP, because TPU is a mature environmentally friendly materials, TPU also has

1. With excellent high tension, high tension, toughness and aging resistance characteristics.

2. high strength, good toughness, abrasion resistance, cold resistance, oil resistance, water resistance, aging resistance and weather resistance, which is incomparable to other plastic materials.

3. It has high waterproof and moisture permeability, wind resistance, cold resistance, anti-bacterial, anti-mold, and many excellent functions, such as warmth, UV resistance and energy release.

Please scan the QR code above to contact us directly.

Post time: Aug-18-2023