TPU-Matte Paint Protection Film

Support customization

Support customization

Own factory

Own factory

Advanced technology

Advanced technology

TPU Matte Paint Protection Film

Durable, Self-Healing & Matte Finish | Automotive PPF

TPU Matte Paint Protection Film (PPF) is a durable urethane coating designed to preserve your car’s original paint while delivering a sleek, long-lasting matte finish. Engineered with advanced thermoplastic polyurethane (TPU) technology, this innovative film offers exceptional durability and aesthetics, making it the ideal solution for car owners seeking to combine protection with style.

The film is tailored to fit complex surfaces seamlessly without leaving any adhesive residue. It features self-healing technology that automatically repairs minor scratches and damage without the need for heat, ensuring your vehicle’s paint remains flawless. With its cutting-edge design, TPU Matte PPF provides reliable, long-lasting protection for your car in any condition.

Durable Protection for Everyday Challenges

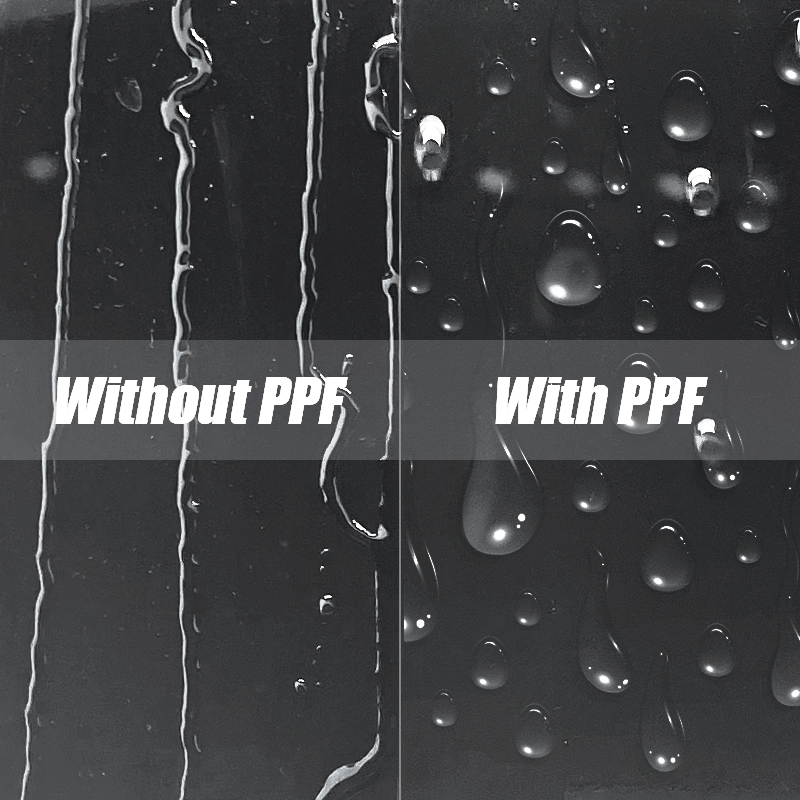

Comprehensive Surface Protection: The TPU Matte PPF shields your car from scratches, stone chips, and environmental damage like UV rays and acid rain. Its durable urethane coating preserves your car’s original paint in all conditions.

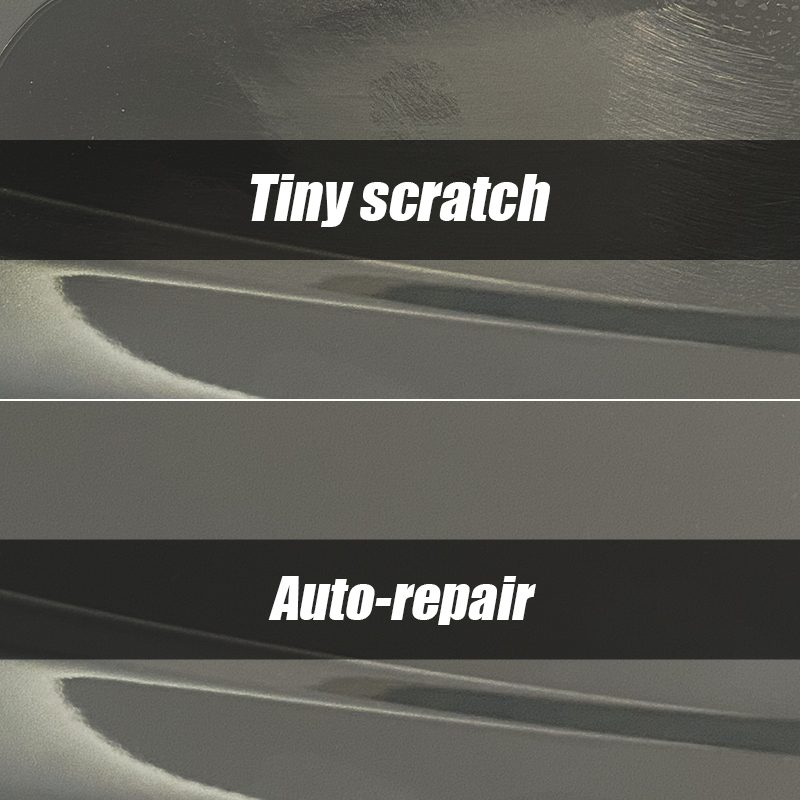

Self-Healing Technology: Minor scratches and swirl marks disappear automatically with the film’s self-healing coating, which does not require heat to activate. This ensures your car remains flawless at all times.

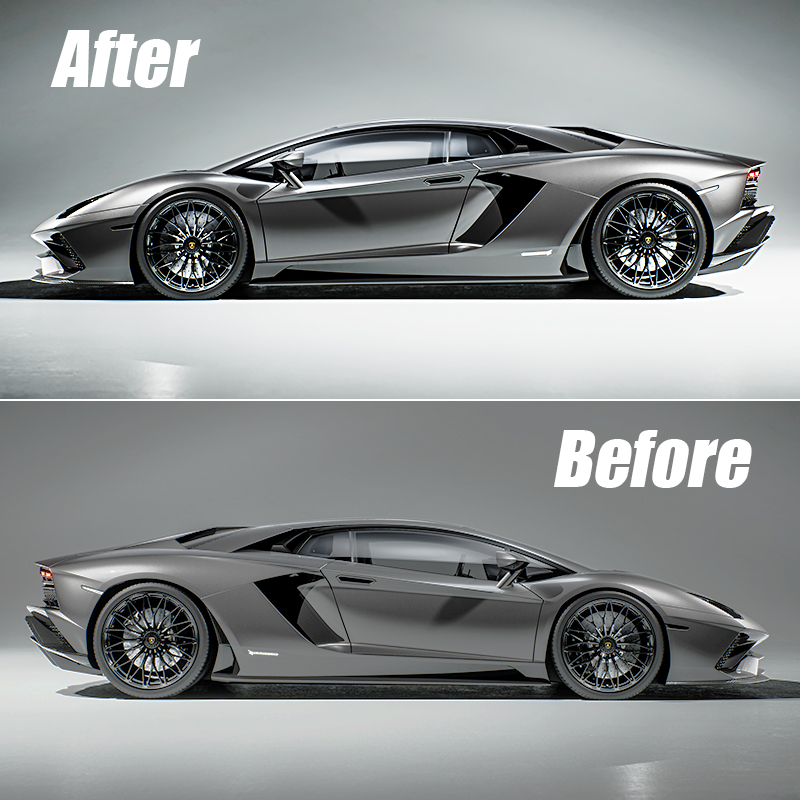

Modern Matte Finish for a Sophisticated Look

Matte Finish Transformation: The film converts your car's paint to a long-lasting, matte finish that adds a sleek, contemporary appearance while retaining the original color beneath.

Non-Yellowing Clarity: The film’s high-quality construction resists yellowing over time, maintaining a clean, uniform matte appearance.

Perfect Fit for Complex Surfaces

Seamless Application: Designed to fit complex surfaces and curves, the TPU Matte PPF adheres flawlessly without leaving any adhesive residue, ensuring a smooth and professional finish.

Why Choose TPU Matte Paint Protection Film?

The TPU Matte Paint Protection Film combines superior protection with a stunning matte aesthetic, making it the perfect choice for car enthusiasts. Its advanced self-healing capabilities and durable construction ensure long-lasting performance and ease of maintenance.

Customer Feedback

Drivers love the TPU Matte PPF for its ability to transform the look of their vehicles while providing reliable protection. The combination of style, durability, and functionality has made it a popular choice for modern car owners.

The Best Film in Good Hands

XTTF PPF materials offer the strongest protection for paintworks. Customers and dealers can quickly identify the colored ppf film base and recognize that the XTTF PPF has greater clarity and brightness than most other brands. The self-healing XTTF ppf film will keep it in great shape. Alter the appearance of your matte paint to protect it

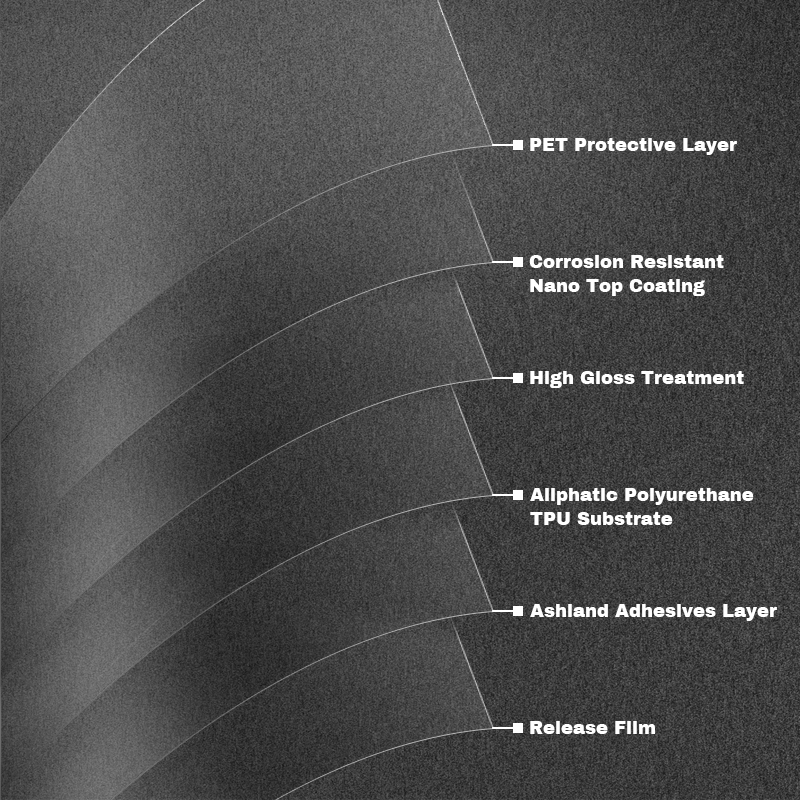

Structure Inside

1. PET Protective Layer

The functional top coating protects the coatings beneath and keeps them from being damaged during manufacturing and shipment.

2. Corrosion Resistant Nano Top Coating

A strong corrosion resistance nano coating is manufactured in Japan, considerably enhancing corrosion resistance to acid, alkali, and salt. When harmed on a modest scale, heat activates self-healing.

3. High Gloss Treatment

Increase the gloss of the paint protection film, and keep it glossy.

4. Aliphatic Polyurethane TPU Substrate

This layer possesses high tensile strength, as well as tear resistance, anti-yellowing resistance, aging resistance, and puncture resistance.

5. Ashland Adhesives Layer

Using high-end adhesive from Ashland , there will be no mark guard and no damage to the paint surface.

6. Release Film

It is frequently utilized as the initial barrier between the composite laminate and the rest of the vacuum bagging components, and it is designed to easily manage the laminate's resin content.

| Model | TPU Matte |

| Material | TPU |

| Thickness | 7.5mil/6.5mil ±0.3 |

| Specifications | 1.52*15m |

| Gross Weight | 11kg |

| Net Weight | 9.5kg |

| Package Size | 159*18.5*17.5cm |

| Coating | Nano hydrophobic coating |

| Structure | 2 layers |

| Glue | Ashland |

| Glue Thickness | 23um |

| Film Mounting Type | PET |

| Repair | Automatic thermal repair |

| Puncture Resistance | GB/T1004-2008/>18N |

| UV Barrier | > 98.5% |

| Tensile Strength | > 25mpa |

| Hydrophobic self-cleaning | > +25% |

| Anti-fouling and Corrosion Resistance | > +15% |

| Glare | > +5% |

| Aging Resistance | > +20% |

| Hydrophobic Angle | > 101°-107° |

| Elongation at Break | > 300% |

| Features | Test Method | Results |

| Release Force N/25mm | paste on steel board, 90° 26℃ and 60%, GB2792 | 0.25 |

| Initial Tack N/25mm | under 24℃ and 26%, GB31125-2014 | 9.44 |

| Peel Strength N/25mm | paste on steel board, 180° 15 Minutes under 29℃and 55%, GB/T2792-1998 | 9.29 |

| Holding Power(h) | paste on steel board,hang on by 25mm*25mm*1kg weight under 29℃ and 55%, GB/T4851-1998 | >72 |

| Gloss(60°) | GB 8807 | ≥90(%) |

| Application Temperature | / | +20℃ to +25℃ |

| Service Temperature | / | -20℃ to +80℃ |

| Humidity Resistance | 120 hours exposure | No Detrimental Effect |

| Salt-spray Resistance | 120 hours exposure | No Detrimental Effect |

| Water Resistance | 120 hours exposure | No Detrimental Effect |

| Chemical Resistance | 1hour diesel oil immersion,4hours antifreeze immersion | No Detrimental Effect |

| Gloss | >90(%) | 60 degree/GB 8807 |

| Aging Test 1 | 7 days under 70°C | No adhesive residue with heat |

| Aging Test 2 | 10 days under 90°C | No adhesive residue without heat |

| Tensile Strength | > 25mpa | tensile strength |

| Hydrophobic Self-cleaning | > +25% | Hydrophobic self-cleaning |

| Anti-fouling and Corrosion Resistance | > +15% | Antifouling and corrosion resistance |

| Glare | > +5% | Glare |

| Aging Resistance | > +20% | Aging resistance |

| Hydrophobic Angle | > 101°-107° | Hydrophobic angle |

| Elongation at Break | > 300% | Elongation at break |

| Self-healing Rate | 35℃ Water 5S 98% | Self-healing Rate |

| Tear Strength | 4700psi | Tear Strength |

| Maximum Temperature | 120℃ | Maximum Temperature |

Highly Customizable Service

Being a distributor is the most important kind of cooperation in our commercial relationships. We exclusively work on an exclusive basis, and once you begin introducing the brand to your market, XTTF will not be shipped to your competitors.

XTTF super factory can provide various customization services based on customers' needs. With high-end equipment in the United States, collaboration with German expertise, and strong backing from German raw material suppliers. XTTF's film super factory can meet all of its customers' needs.

XTTF can create new film features, colors, and textures to fulfill the specific needs of agents who want to personalize their unique films. Don't hesitate to get in touch with us right away for additional information on customization and pricing.

contact us

Highly Customization service

BOKE can offer various customization services based on customers' needs. With high-end equipment in the United States, collaboration with German expertise, and strong backing from German raw material suppliers. BOKE's film super factory ALWAYS can meet all of its customers' needs.

Boke can create new film features, colors, and textures to fulfill the specific needs of agents who want to personalize their unique films. Don't hesitate to get in touch with us right away for additional information on customization and pricing.