XTTF TPU-Quantum-PRO Clear Paint Protection Film 1.52*15M

Support customization

Support customization

Own factory

Own factory

Advanced technology

Advanced technology

XTTF TPU-Quantum-PRO Clear Paint Protection Film – The Ultimate in Automotive Protection

The XTTF TPU-Quantum-PRO Clear Paint Protection Film is designed to provide cutting-edge protection for your vehicle’s paint. This advanced thermoplastic polyurethane (TPU) film ensures your car stays protected from scratches, road debris, and environmental damage, all while maintaining its original glossy appearance. With its innovative self-healing technology, the film offers long-lasting, crystal-clear protection without requiring heat activation, making it one of the most advanced paint protection solutions available today.

A light blue PPF base which makes it distinctive from others.

10% visually brighter than other brands.

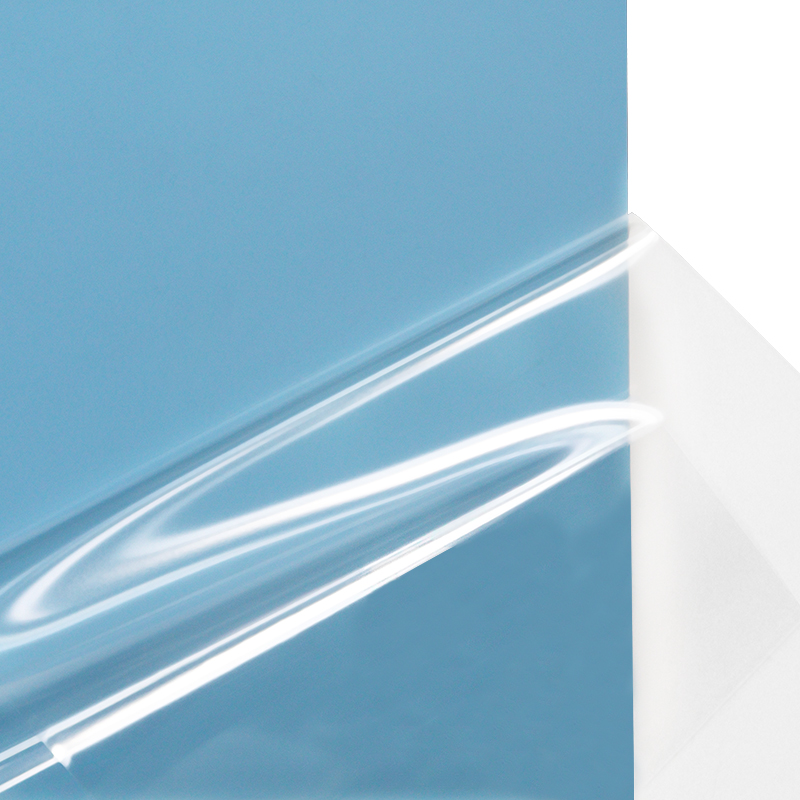

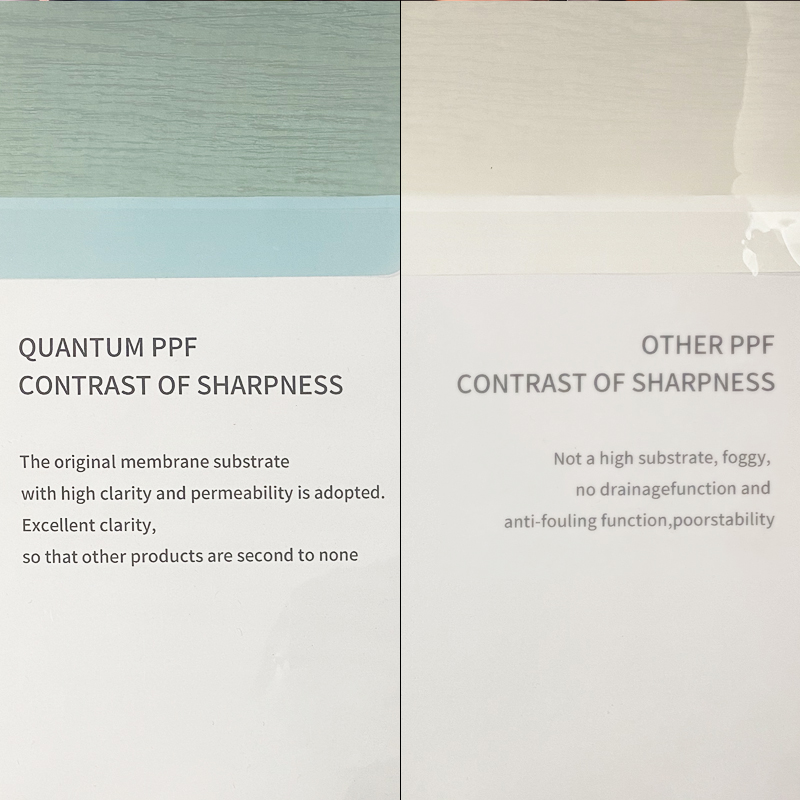

High clarity is adopted.

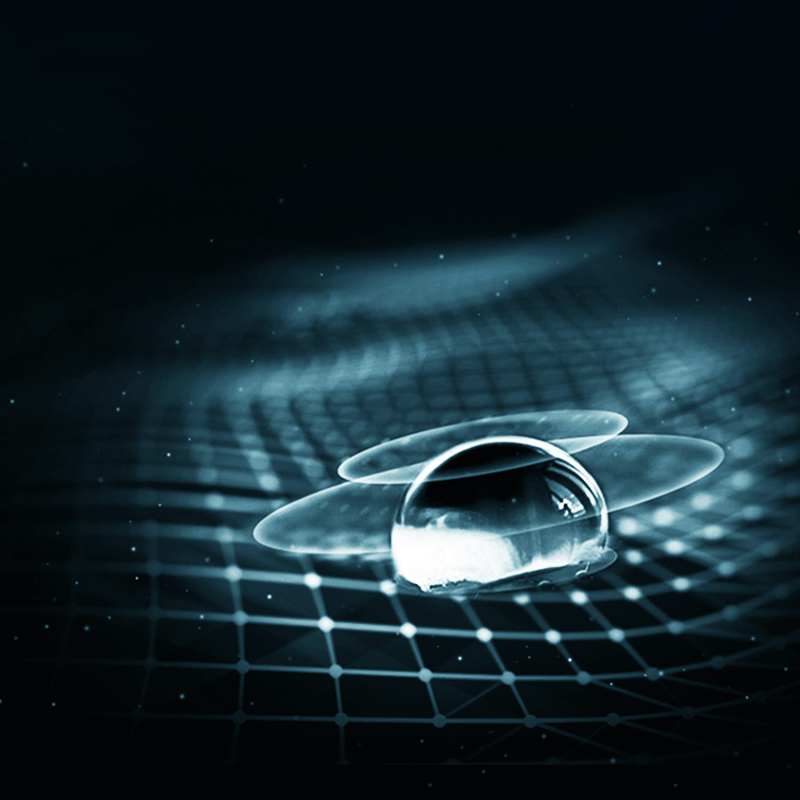

The fifth generation nano superconducting hydrophobic coating.

Features of TPU-Quantum-PRO

The Gloss Everyone Wants

TPU-Quantum-PRO is one of the most advanced paint protection films on the market. The brightness is approximately 40% above the original paint and 10% brighter than other PPF films. A spray paint layer is easily scratched, and an average scratch can quickly (and permanently) reduce a car's value by 10~25 percent per year. XTTF PPF provides effortless protection for your car with a consistent, smooth clear finish that also maintains the vehicle's value.

Maximum Durability & Protection

The XTTF TPU-Quantum-PRO PPF is engineered to give maximum surface protection in the most high-impact regions imaginable. It is also extremely resistant to solvents, acids, bases, insect splatter, and bird droppings. Other distinguishing characteristics include resilience to room temperatures ranging from -40 to 150 degrees Celsius, harsh weather conditions such as a sandstorm and sea breeze zone, and an effective protective temperature ideal for any driving situation.

Auto-healing From Scratch 24/7

Heat-activated self-healing topcoats are already obsolete, and the XTTF TPU-Quantum-PRO self-heals minor scratches and swirl marks at room temperature. XTTF offers far more protection than masking tape or unpleasant spray-on alternatives. Our patented film formulation does not yellow when exposed to UV light, making shielded regions practically invisible.

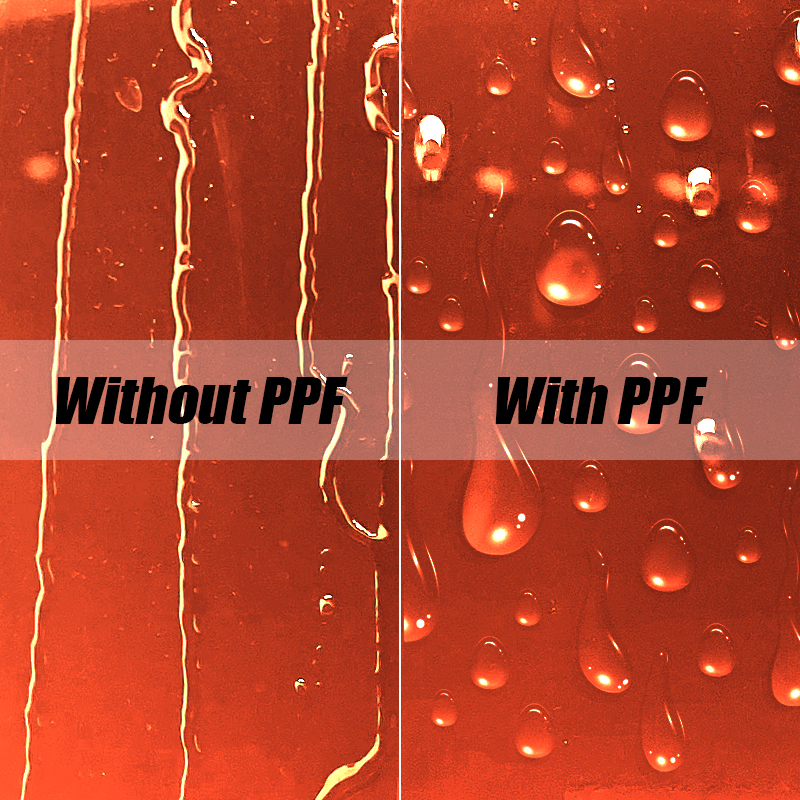

Stain Resistant

Don't be concerned about specs, stains, or splotches caused by pollutants, much as debris mixed with water leaves marks on the vehicle when it rains. XTTF PPF not only creates a significant barrier against pebbles and road debris, but its hydrophobic function causes rain to form large droplets and leaves no visible watermark.

Why Choose XTTF TPU-Quantum-PRO Clear Paint Protection Film?

The colored ppf film base is highly recognizable by the dealers and customers, and they can clearly feel that the XTTF PPF has higher clarity and brightness compared to other brands. Self-healing XTTF ppf film will keep it appearing flawlessly pristine. Alternatively, protect your gloss paint with a fresh, brighter look! Available in two different thicknesses to provide the necessary protection for both external and interior surfaces.

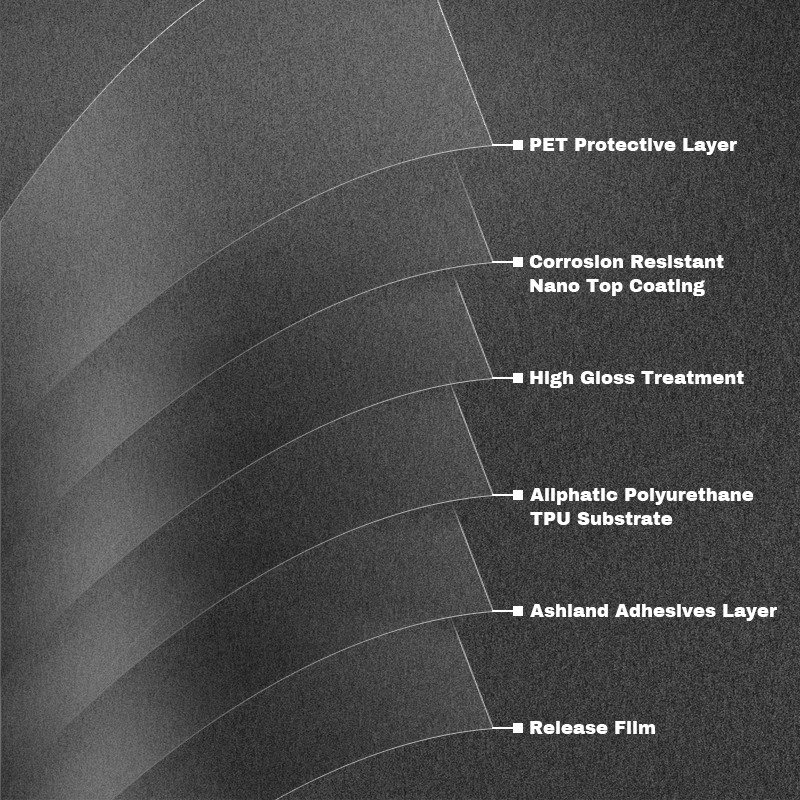

Product structure

1. PET Protective Layer

The functional top coating acts as the surface layer of the PPF. and keeps them from being damaged during manufacturing and shipment.

2. Corrosion Resistant Nano Top Coating

A strong corrosion resistance nano-coating is manufactured in Japan, considerably enhancing corrosion resistance to all kinds of chemicals. When harmed on a modest scale, heat activates self-healing.

3. High Gloss Treatment

This layer increases the gloss of the paint protection film.

4. Polyurethane TPU Substrate

The bulk of PPF is polyurethane which determines the thickness and strength of the paint protective sheet. This layer has tensile strength, abrasion resistance, anti-yellowing resistance, aging resistance, and puncture resistance.

5. Ashland Acrylic Adhesive

With Ashland's high-end adhesive, there will be no mark guard and no damage to the paint surface while providing adhesion endurance.

6. Polyester Release Liner

This is the bottom layer of the PPF, and when it is removed, the material that forms the bond to the vehicle surface is revealed.

| Model | Quantum PRO |

| Material | TPU |

| Thickness | 6.5mil±0.3 |

| Specifications | 1.52*15m |

| Gross Weight | 11kg |

| Net Weight | 9.5kg |

| Package Size | 159*18.5*17.5cm |

| Coating | Nano hydrophobic coating |

| Structure | 3 layers |

| Glue | Ashland |

| Glue Thickness | 23um |

| Film Mounting Type | PET |

| Repair | Automatic thermal repair |

| Puncture Resistance | GB/T1004-2008/>18N |

| UV Barrier | > 98.5% |

| Tensile Strength | > 25mpa |

| Hydrophobic self-cleaning | > +25% |

| Anti-fouling and Corrosion Resistance | > +15% |

| Glare | > +5% |

| Aging Resistance | > +20% |

| Hydrophobic Angle | > 101°-107° |

| Elongation at Break | > 300% |

| Features | Test Method | Results |

| Release Force N/25mm | paste on steel board, 90° 26℃ and 60%, GB2792 | 0.25 |

| Initial Tack N/25mm | under 24℃ and 26%, GB31125-2014 | 9.44 |

| Peel Strength N/25mm | paste on steel board, 180° 15 Minutes under 29℃and 55%, GB/T2792-1998 | 9.29 |

| Holding Power(h) | paste on steel board,hang on by 25mm*25mm*1kg weight under 29℃ and 55%, GB/T4851-1998 | >72 |

| Gloss(60°) | GB 8807 | ≥90(%) |

| Application Temperature | / | +20℃ to +25℃ |

| Service Temperature | / | -20℃ to +80℃ |

| Humidity Resistance | 120 hours exposure | No Detrimental Effect |

| Salt-spray Resistance | 120 hours exposure | No Detrimental Effect |

| Water Resistance | 120 hours exposure | No Detrimental Effect |

| Chemical Resistance | 1hour diesel oil immersion,4hours antifreeze immersion | No Detrimental Effect |

| Gloss | >90(%) | 60 degree/GB 8807 |

| Aging Test 1 | 7 days under 70°C | No adhesive residue with heat |

| Aging Test 2 | 10 days under 90°C | No adhesive residue without heat |

| Tensile Strength | > 25mpa | tensile strength |

| Hydrophobic Self-cleaning | > +25% | Hydrophobic self-cleaning |

| Anti-fouling and Corrosion Resistance | > +15% | Antifouling and corrosion resistance |

| Glare | > +5% | Glare |

| Aging Resistance | > +20% | Aging resistance |

| Hydrophobic Angle | > 101°-107° | Hydrophobic angle |

| Elongation at Break | > 300% | Elongation at break |

| Self-healing Rate | 35℃ Water 5S 98% | Self-healing Rate |

| Tear Strength | 4700psi | Tear Strength |

| Maximum Temperature | 120℃ | Maximum Temperature |

Highly Customizable Service

BOKE's super factory can provide various customization services based on customers' needs. With high-end equipment in the United States, collaboration with German expertise, and strong backing from German raw material suppliers. BOKE's film super factory can meet all of its customers' needs.

Bock can create new film features, colors, and textures to fulfill the specific needs of agents who want to personalize their unique films. Don't hesitate to get in touch with us right away for additional information on customization and pricing.

contact us

Highly Customization service

BOKE can offer various customization services based on customers' needs. With high-end equipment in the United States, collaboration with German expertise, and strong backing from German raw material suppliers. BOKE's film super factory ALWAYS can meet all of its customers' needs.

Boke can create new film features, colors, and textures to fulfill the specific needs of agents who want to personalize their unique films. Don't hesitate to get in touch with us right away for additional information on customization and pricing.